1-Problem identification. 2-Data gathering and categorization. 3-International codes and standards best practices. 4-Gap analysis and assessment audit. 5-Root cause analysis. 6-Optimum solution selection based on client capability. 7-Develop engineering design for selected solution. 8-Supervise and follow up for solution implementation. 9-Awareness training to avoid repeated problems. 10-Continuous improvement.

Through Gap Analysis (GA) we help our clients identify the difference between the current and desired status of their asset integrity in order to develop strategies to meet their business objectives. The main purpose of GA in Asset Integrity Process is to identify the areas where the Asset does not meet the desired level of performance. Generally speaking, GA assessment is a multi-disciplinary approach to determine whether equipment suits continued service.

Defining the assets to be analyzed, the process to be reviewed, the stakeholders involved.

2) Collecting data.Information about processes, procedures and systems applied in place.

3) Analyzing the data.Identifying gaps in the Asset Integrity Management System.

4) Developing recommendations.Addressing the identified gaps.

GA is an indispensable tool that helps to identify areas where the asset integrity management system is not meeting regulatory requirements, which can help to improve safety.

2) Downtime Reduction:By identifying gaps in the asset integrity management system, GA can help to reduce downtime caused by equipment failure.

3) Efficiency Improvement:GA helps to identify areas where the asset integrity management system can be improved leading at the same time to efficiency increase and costs reduction.

Plant Condition Integrity System (PCIS) is a data management system that stores, organizes and analyzes inspection and mechanical integrity data from all organization facilities and equipment and links it across selective technology platform. Oil&Gas process- industry regulations require facilities to maintain huge amounts of mechanical and electrical integrity data. CIS conduct gap analysis to identify the gap which is the main key step to walk on the integrity road. That’s while keeping thousands of individual components each with their own

Mechanical inspection damage and repair histories. Digital transformation of client facilities requires such data management system that does not only stores the data but also turns it into actionable information used to maximize safety, enhance productivity and optimize budgets for their asset life-cycle. PCIS acts both as digital transformation and the warehouse system for Mechanical Integrity data management system.

We provide clients the flexibility to decide and choose modules according to their business needs. Based on our clients' core framework, we collect suitable pivotal equipment configuration, user interface management and inspection functionality which is required to form the basic inspection data management solution. Our clients later use it to select a combination of modules meeting their business needs.

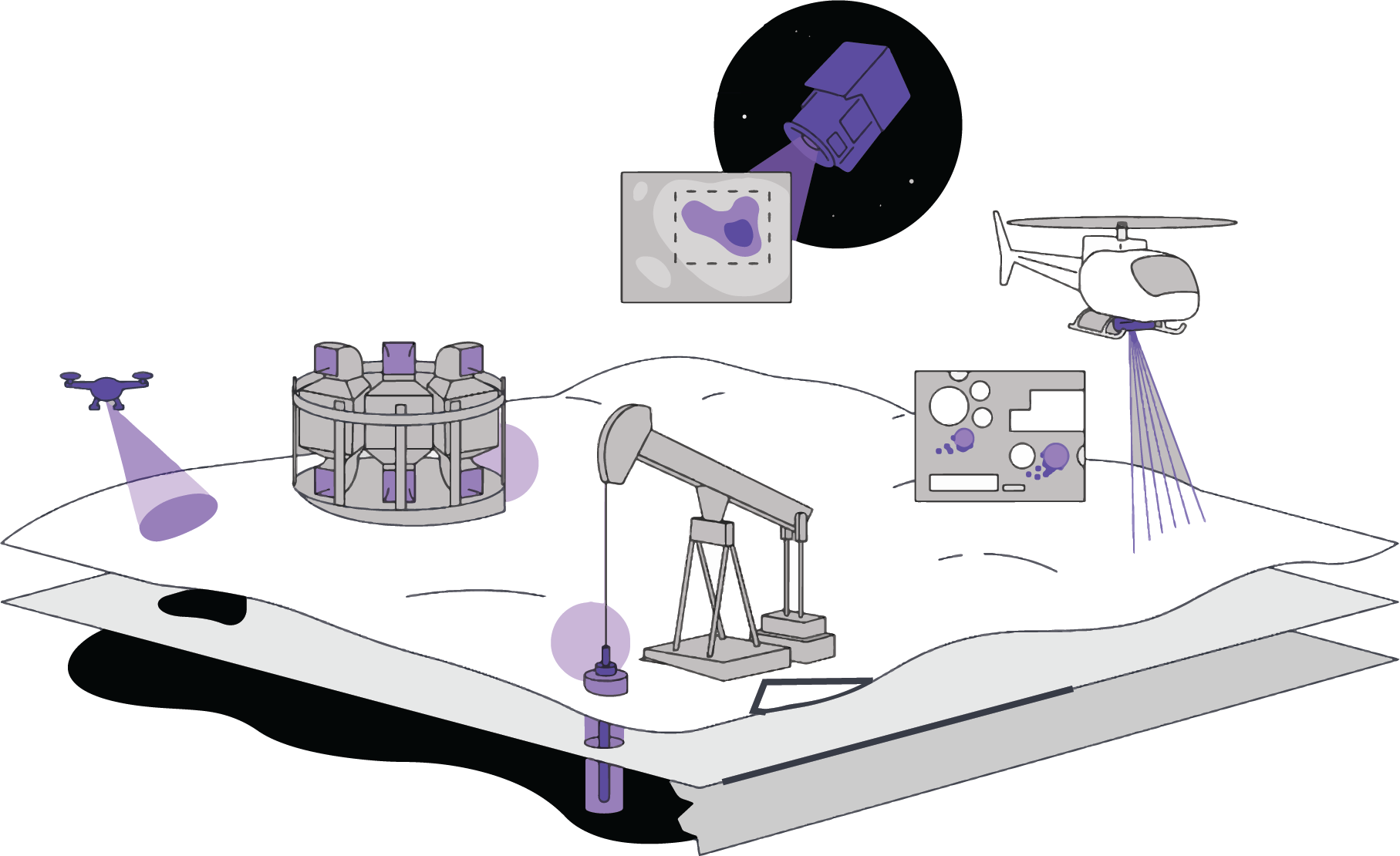

Transportation process for O&G product normally carried out with transportation pipeline, coursing pressure upgrade & reduction station. Within CIS we provide comprehensive range of Pipeline Integrity services; Inspection, Integrity, Crawlers, Drones, Monitoring.

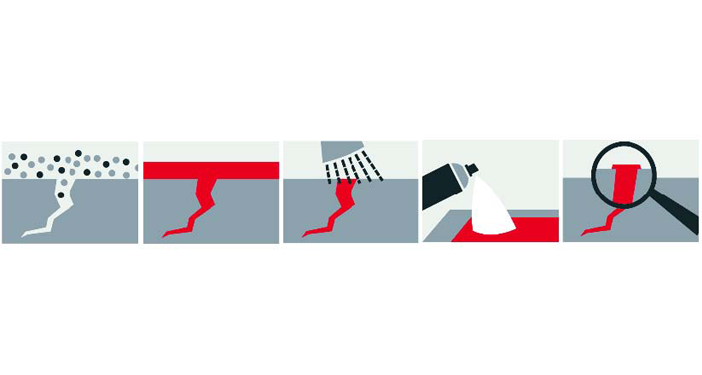

In cooperation with selective approved vendors, we provider NDE Advance technology to evaluate solution for buried and aboveground pipeline, which help your operation maximize safety, extend lifetime and achieve regulatory compliance. which help your operation maximize safety, extend lifetime and achieve regulatory compliance.

No matter the current condition of the pipeline; no matter the expected damage mechanisms, pecialize team from CIS review assure and provide integrity service for your pipeline through lifecycle. Simplifying your pipeline integrity condition management, we provide the following: -Asset condition monitoring. -Inspection Data Management Software. -Integrity data management software. -Coating & Insulation assessment. -Risk-Based Inspection. -Pipe-to Soil Potential risk & Cathodic Protection assessment. -Corrosion measurement.

For those areas where the construction of pipelines is difficult to access and those area often aren’t inspected as frequently as they should be. Between the construction, operation and integrity phase, potential damage might be their which will cost a lot after operation. Our affiliate remote monitoring solutions keep you informed of your line’s condition at all times. -Permanently – installed guided wave Ultrasonic (GUL) collars to monitor large pipeline volumes. Limits visits to hard to access line which Identifies changes of the less than 1% in pipe cross-sections. -Dron’s support: Drones for onshore/offshore pipelines Emergency response Infrared imag ing for progress construction phases, leak location and real time spill monitoring.