From this point of view CIS Material Protection Strategy will help your organization to build up your own CMS and enhance your assets and valuable it ems protection plan.

Pre surface preparation inspection

Blasting visual Inspection

Surface salt contamination inspections

Surface Roughness inspection

Dry film Thickness

Holiday Detection

Pull off Adhesion tests

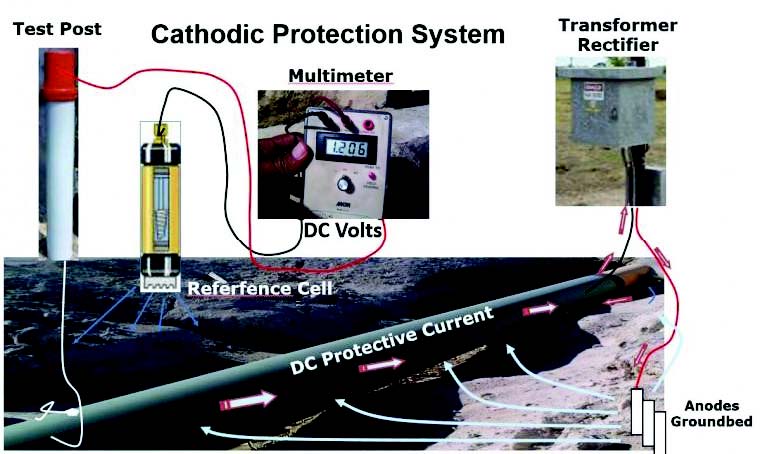

Corrosion doesn’t stop, but a corrosion management program can help to control it. By implementing one, organizations can proactively plan to improve the way critical assets are designed, operated, & maintained thereby reducing the cost of damage control and unexpected failures from corrosion. A CMS is most successful when it is integrated within an organization’s overall management system and tools are provided to create consistent processes and operating procedures so that employees from the top down can respond holistically and effectively when faced with corrosion-related incidents. A strategy for Corrosion Management coupled with training that incorporates lessons learned, case studies shared experiences, and best practices provides a foundation to guide companies towards stronger

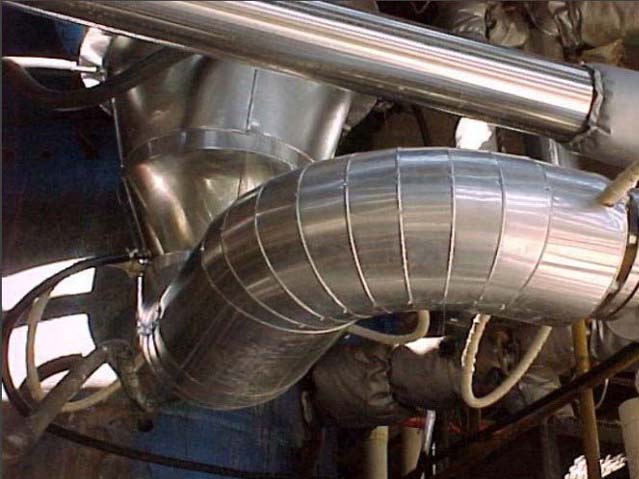

Insulation is a cost-effective, energy-saving product that saves money for individuals & businesses through lower utility bills while increasing the comfort levels for all building occupants Adequate levels of insulation for industrial processes have helped make the industry more efficient and more profitable by cutting energy losses and decreasing production costs. By avoiding the added energy generation necessary to heat and cool buildings, insulation continues to be a benefit to the environment by helping to reduce pollution emissions. Insulation products play a significant energy savings role by reducing energy use in homes, office buildings, and manufacturing plants.

Surface preparation

Coating inspection

Reviewing the insulation materials PDS and procedures.

Insulation installation inspection

Insulation thickness inspection

Insulation securements and sealing

Weather protection sheets installation and inspection